There has been a lot made of TSMC’s ability, or potential lack thereof, to deliver on the huge demand for 7nm silicon now being brought to bear on the pureplay foundry by the success of both AMD’s Ryzen CPUs and its Radeon RX 5700 XT and RX 5700 graphics cards… hell, its processors can even be used for ray tracing now. But both AMD and TSMC are keen to show a united front to prove they have the capabilities and the capacity to supply the most advanced node around for the best CPUs for gaming and the best graphics cards.

And TSMC has a vested interest in making sure AMD’s chips get made, outside of its position as the lead foundry, because it’s also a datacentre customer. Though I’m sure it gets ‘mate’s rates’ on the EPYC 2 server chips it’s deployed in its datacentre. If not it’s just snaffled a few straight off its own production lines…

At the recent ‘Rome in Rome’ investor presentation Godfrey Cheng, TSMC’s head of global marketing, took to the stage alongside AMD’s Mark Papermaster to demonstrate its ability to supply AMD, and its customers, plenty of 7nm silicon. Because if you fail to deliver the right product at the right time you “commit the cardinal sin of actually leaving demand on the table, and that’s not what we do.”

Since a report came out suggesting TSMC was lengthening the lead times on future 7nm chip production there has been a lot of speculation about what that might mean for AMD. Not least because its closest rival, Intel, has had its own very public production problems.

“As CTO, I’m meeting with customers every week,” says The Papermaster, “and the question I get is: ‘How is TSMC going to have the capacity to be able to deliver the volume when others at this technology node have run into challenges?’”

“In raw aggregate capacity,” says Cheng in response, “we’re actually three times the capacity of our next nearest foundry competitor. This means that we have approximately 12,000,000 12-inch equivalent wafers in terms of raw capacity.

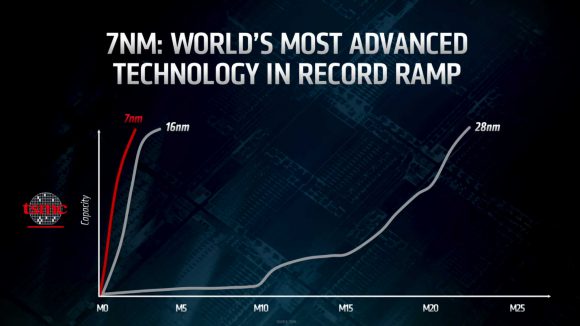

“Now, talk about raw capacity is not enough. There’s another aspect of capacity, which is the technology ramp. And if you look at the ramp for the N7 node… you can see our N7 node has actually been very successful. Not only because it’s the most advanced node in the world, but we’ve been able to ramp it as quickly – actually better – than any other node in the history of TSMC.”

And the technology ramp is vital for a new node that’s suddenly being used by a whole host of different product. And remember, it’s not just AMD demanding a slice of TSMC’s 7nm production capabilities, the polo necks over at Apple want their pound of silicon too.

“The reason why the ramp is such a critical element of a product,” says Cheng, “is that with any product there is a life cycle. And if you cannot deliver a product within a certain timeframe where the demand is hot, we commit the cardinal sin of actually leaving demand on the table, and that’s not what we do.”

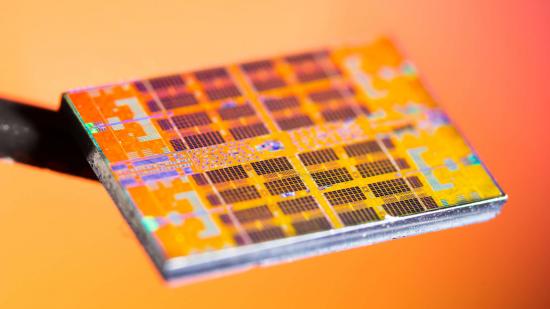

In a room full of AMD datacentre clients Cheng also felt it necessary to point out the trust TSMC’s multi-billion dollar business has in AMD’s latest product, showing a suite of EPYC 2-based servers churning away in their own datacentre.

“Not only is TSMC, a strong partner for AMD,” says Cheng, “but we’re also customer.”