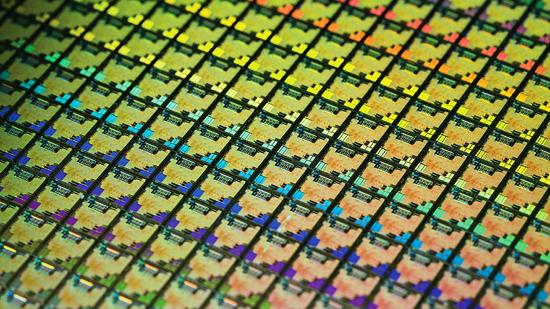

AMD CTO Mark Papermaster believes the red team’s future designs will have the flexibility to utilise various semiconductor foundries going forward. While AMD has recently made the change from GlobalFoundries, once upon a time AMD’s manufacturing division, to TSMC for 7nm, AMD’s chief technology officer doesn’t see the need for a continued reliance on what TSMC is cooking up next.

TSMC, a pure play foundry, deals with clients such as Nvidia, AMD, and even the likes of Apple. But, during an interview with AnandTech, CTO Mark Papermaster explained how AMD’s flexibility in supply chain and product design will leave it open to various other’s process technologies. Even Samsung, the reigning semiconductor champ, could be in the running to build future AMD product.

TSMC and Samsung rule the node density roost for the time being. GlobalFoundries recently ducked out of the 7nm fight, instead focusing its efforts on continued expansion of high yield processes such as 14nm. AMD’s Zen 2-based 64-core EPYC processor is set to utilise two separate nodes: the discrete processing cores, or chiplets, are the domain of TSMC, and its centralised I/O die use the rock-solid 14nm foundations from AMD’s close-knit partner GlobalFoundries.

“The march for high performance has brought us to Zen 2 and the ability to leverage multiple technology nodes,” Mark Papermaster says to AnandTech. “What we’re showing with Rome is a solution with two foundries, with two different technology nodes. It gives you an idea of the flexibility in our supply chain that we’ve built in, and gives you explicit example of how we can work with different partners to achieve a unified product goal. On the topic of Samsung, we know Samsung very well and have done work with them.

“…we work with the various supporting industries as well as working with the foundries. We are always looking into future nodes across the industry,” Papermaster continues.

This isn’t the first time Samsung has been on the periphery for AMD’s manufacturing needs. Back when 14nm first appeared on the scene, AMD told analyst Patrick Moorhead that it had already manufactured products with Samsung, and that the company was on call should AMD ever need further capacity. This would of been easy enough as GloFo licensed 14nm from Samsung in the first place.

According to the latest research from IC Insights, Samsung is currently the global leader in semiconductor manufacturing. The South Korean company is expected to have raked in $83bn worth of semiconductor business by the end of 2018. It also aims to have an early-stage 5nm low-power process by 2019, and a 4nm process by 2020.

AMD’s leapfrogging design teams have been confirmed to be working on AMD Zen 2, Zen 3, Zen 4, and beyond. Indeed Zen 3 is set for release in 2020, potentially giving the Zen 2 chips only a year to live. AMD could be looking to cast a wider net for semiconductor manufacturing going forward, cherry-picking the best nodes with the best yields to keep it competitive.

With GlobalFoundries now out of the running for 7nm, AMD’s future product will almost certainly have to move away from the company. The red team’s flexible chiplet, modular CPU design mantra may allow for yet another fab to make it into gamers’ PCs.

This product design flexibility could be a powerful tool in AMD’s hands in its efforts to win over the competitor’s market share. While Intel is dependent on its own manufacturing process – which can be both a blessing and a curse at times – the red team is on the cusp of turning its own lack of internal fabrication access into an advantage.