Intel’s head engineering bod, Murthy Renduchintala, has suggested that anyone thinking the recent delays to their 10nm volume production schedule has pushed back the subsequent transition to 7nm is making a “premature assumption.”

We’re stuck on 14nm at the moment, and you can find the best Intel processors here.

He was presenting at the JP Morgan Global Technology, Media, and Communications Conference last night and still couldn’t give any indication as to when the delayed 10nm production process would bear fruit in volume. When they announced the delay during a recent earnings call Brian Krzanich, Intel CEO, gave a vague 2019 window, and Renduchintala wouldn’t narrow that down.

“I’ve given ourselves no specific timeline,” he says. “Again it’s when the economic timing makes greater sense for us in terms of when we hit the right point in the yield curve. So, I think we’ll take it with a little bit of wait and see, but certainly in my mind we’ll be ready as soon as we believe there is a significant capability to cross over on cost structure point of view.”

But despite not knowing when exactly the 10nm lithography will cover a broader range of their products (there are some weak-heart mobile 10nm Cannon Lake chips floating around in a low-power Lenovo) Renduchintala was adamant that you couldn’t look at those delays and expect the same with the move to the 7nm production node.

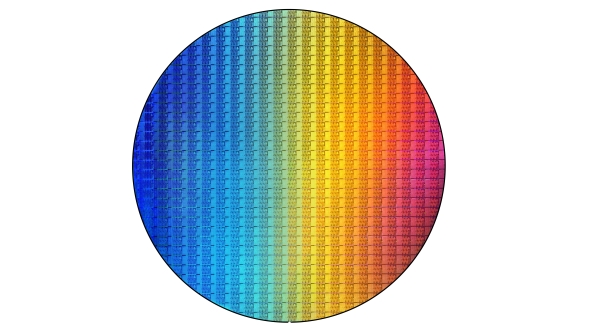

“I think that would be a premature assumption,” he says. “If you look at the technical risk factors in 7- versus 10-nanometers, they’re very different. 10-nanometer is basically with the generation that was really focusing on delivering 2.7 ex-scaling in an environment that wasn’t assisted by EUV.”

Extreme Ultraviolet lithography (EUV) is the technology which will eventually allow cheaper, less complex, but more dense processors to be created at the 7nm level and beyond for both Intel and AMD. And that makes it a very different beast to the current 10nm design, with far fewer steps involved in production with some estimates putting the process at nine steps versus the current 34 steps that the 10nm design requires right now.

That should potentially alleviate some of the yield issues Intel have suffered at 10nm, but then we’re talking about a brand new production process with new equipment, and expecting that to run without a hitch first time is ambitious at best.

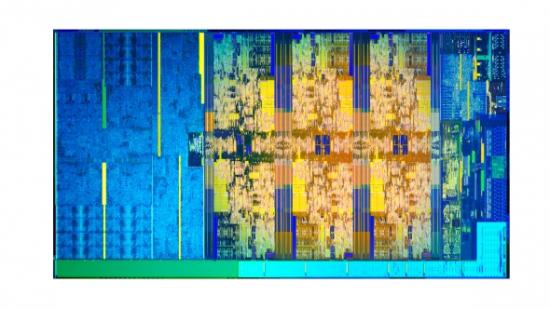

But once 10nm does become a genuine thing for Intel don’t expect it to be quickly replaced by the subsequent 7nm lithography even when it does come good. Intel have found a huge amount of intra-node performance within the 14nm design, delivering a 70% speed bump from the first 14nm chips to the current Coffee Lake CPU. And they’re going to continue down that path.

“That isn’t a one off strategy for us,” Renduchintala says. “We’ll continue to see nodes living longer and an overlap of one node as we transition into another node and it will be a case of make before break, mix and match type capability. So, I think you’ll see that being a greater and greater part of our product roadmap going forward.”

The 14nm chips will continue on until the beginning of 2019 with the 8th Gen design, and from there Intel will begin moving on to 10nm and the 9th Gen cores.

“I’m excited about where we are in nine,” says Renduchintala. “Clearly very aware of the competitive environment, and I am sure we’re going to need to deliver our very best in order to make sure we maintain our lead.”

I’m sure they’re going to have to be at the top of their game too, especially given that the 7nm AMD Zen 2 processors could well be on the market by then…